返回上层

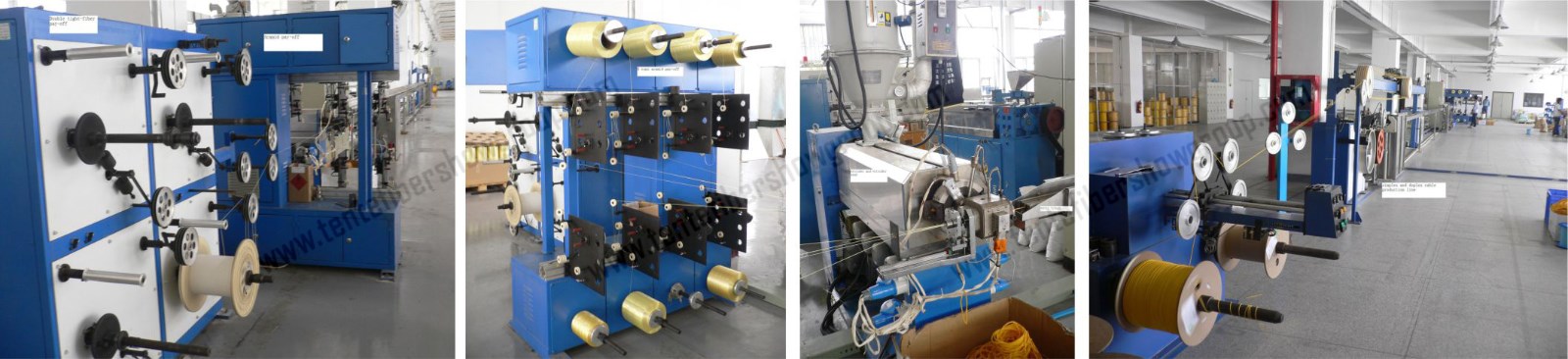

室内缆及皮线缆生产设备

Indoor Cable and FTTH cable sheathing Line

Application of the line

The line is mainly used to produce 2 core indoor optical cable, Include: simplex cable, Duplex cable, FTTH cable and so on.

Line configuration

1 PN800 wire pay-off 1

2 4 tight-fiber and optical fiber pay-off frame 1

3 PN400 FRP or wire pay-off 2

4 10 cops aramid pay-off 1

5 SJ45×25 extruder and one head 1

(With feed, compound dryer device and master batch) 1

6 4m hot water trough and water tank 1

7 12m cooling water trough and refrigerating system 1

8 Blow dryer 1

9 Diameter control system 1

10Φ500 single wheel capstan 1

11 Double reel take-up(cumulating:100m) 1

12 Electric control system 1

Tight coating optic-fiber dia. | Φ0.6mm,Φ0.9mm |

Cable diameter | Φ2.0mm Φ3.0mm |

Size of FTTH cable | 2.0*3.0mm |

2.0*5.0mm | |

Size of tight fiber pay-off reel | PN400mm~PN630mm |

Size of optical fiber pay-off reel | PN 235 |

Size of take-up reel | PN400~PN630 |

Pay-off tension of tight fiber | 0.5N-1.5N±0.05N |

Pay-off tension of tight fiber | 0.4N-1.5N±0.05N |

Take-up tension | 3N-20N |

Aramid cops | 10 |

Aramid pay-off tension | 0.5N-3N±0.05N(adjustable) |

Line speed | |

Extra-attenuation | ≤0.02dB/Km |

Line operation direction | appointed by consumer |

Line color | appointed by consumer |

Power supply | |

Line centre height | 1000mm |

Application of the line

The line is used to extrude tight buffer fiber which the diameter is 0.6mm and 0.9mm.The extruding material can be LSZH, PVC.

Line configuration

1 2 spools optical fiber pay-off 1

2 Preheating and dry device 1

3 One extruder SJ30×25 one self-center head 1

(With feed, compound dryer device and master batch) 1

4 4M Hot water trough 1

5 Hot water tank 1

6 12 M cooling trough 1

7 Cooling water tank (with refrigerating device) 1

8 Blow dryer device 1

9 Diameter control system 1

10 Φ400 capstan 1

11 Dual reel take-up for tight buffer fiber 1

12 Electrical control system 1

Number of optical fiber Pay-off | 2 spools |

Optical fiber pay-off tension | 0.4-1.2N |

Optical fiber reel size | φ236×108mm×φ160 |

φ236×236mm×φ160 | |

Structure speed | 300m/min |

Working speed | 250m/min |

Tight buffer fiber dia | 0.6mm , 0.9mm |

Extruded material | PVC, LSZH |

Extra-attenuation | ≤0.02dB/km(1310nm,1550nm) |

Metering accuracy | ≤0.2% |

Installed power | 25KVA |

Operation direction | Appointed by user |

Line color | Appointed by user |

Line dimension | 21m×3m×3m |

- 上一篇:室内缆及皮线缆生产设备

- 下一篇:TPR-H500 系列 皮线缆和室内缆生产线