-

Home

-

Company Profile

Committed to the world class optical communication research and development and innovation, creating...

Passive Components

Patchcord Production Line

Fiber & Cable

Access Network & Datacom Solutions

Product News

Tente Fiber Fusion Splicer

Main Features

5 inches high Resolution colorful LCD display, image can be turned according to position.

Average splice time: 10 second

-

- Home

- About Us

- Product Center

- News Center

- Enterprise Culture

- Contact Us

- 中文 | ENGLISH

返回上层

.jpg)

Micro-encapsulated PLC splitter

Specification For plc Splitter

Description

PLC (Planar Lightwave Circuit) splitters are used to distribute or combine optical signals. It is based on planar lightwave circuit technology and provides a lowcost light distribution solution with small form factor and high reliability.

Fiber optical splitter is used to split the fiber optic light in to several part sat a certain ratio. The fiber optic splitter is an important passive component used in PON FTTX networks. There are mainly two kinds of passive FTTH optical splitters: one is the traditional fused type splitter as known as FBT coupler or FBT WDM optical splitter, which features competitive price; the other is the PLC splitter based on the PLC (Planar Light wave Circuit) technology, which has a compact size and suits for density applications.

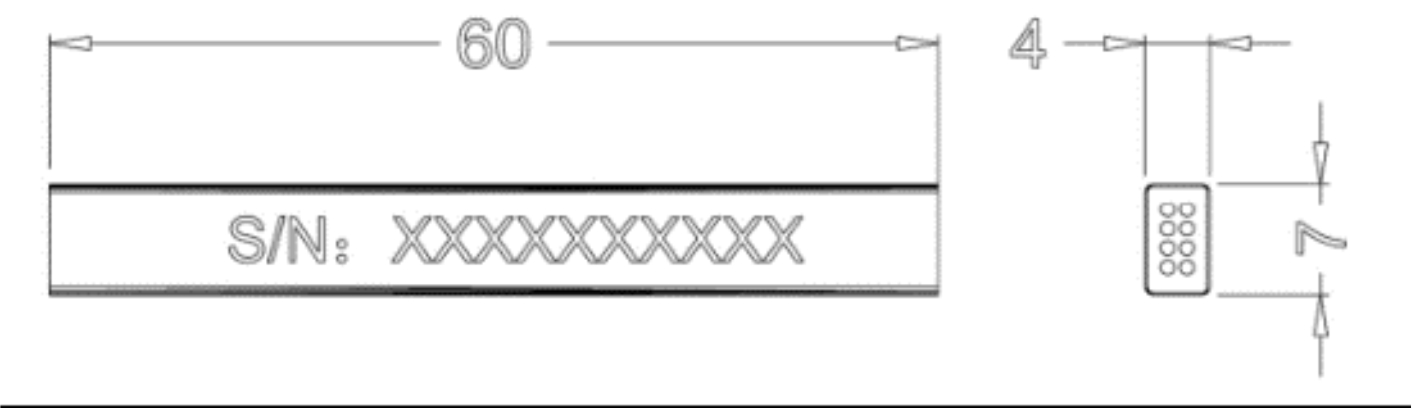

1. Micro-encapsulated PLC splitter

Input port | 1 or 2 | |||

Output port | 2 | 3 | 8 | 16 |

Dimension (nm) | 50*4*4 | 50*7*4 | 60*7*4 | 60*12*4 |

Housing material | Nickel and copper alloy | |||

Connector type | SC/FC/ST/LC with PC/UPC/APC | |||

Port configuration | Ф0.9mm loose tube pigtails | |||

1*8 Micro-encapsulated PLC splitter

PLC Test Specification

Insert/Pull Test

Loss should be within the following limits in reference to the initial value:

- Variation value of Insertion Loss should be ≤0.50 dB in process of testing

- The difference between Initial Value and final test value should be ≤0.30 d

- Return loss should be ≥50 dB in process of Testing

The test shall be conducted under the following conditions:

- Pull/Insert:500 times

- Record a data every 10 times

- Data is recorded 50 times in total

- Clean pins and adapter’s elastic sleeve before recording very time

- Not mechanical damage, such as deformation, loss, corrosion, relaxation and other phenomena

- Test Wavelength 1310‐1550nm

- Required testing interface QTY=log22(Output interface):log2(8)=3

Tensile Test

Loss should be within the following limits in reference to the initial value

- Variation value of Insertion Loss should be ≤0.50 dB in process of testing

- The difference between Initial Value and final test value should be ≤0.30 dB

- Return loss should be ≥55 dB in process of Testing

The test shall be conducted under the following conditions:

- Load: 4 N

- Tensile variation in process of testing: 1N/s

- Duration:60s

- Tensile Point:0.22‐0.28m distance from fiber cable ends

- Test Wavelength 1310‐1550nm

- Required testing interface QTY=log22(Output interface):log2(8)=3

Torsion Test

Loss should be within the following limits in reference to the initial value

- Variation value of Insertion Loss should be ≤0.50 dB in process of testing

- The difference between Initial Value and final test value should be ≤0.30 dB

- Return loss should be ≥50 dB in process of Testing

The test shall be conducted under the following conditions:

- Applied force:7.4N

- The distance between the Torsion point and shell underside is 0.2cm

- Max Torsion Angle: ±180°

- Number of torsions: 100 times

- Torsion Speed:10 Times/min.

- Test Wavelength 1310‐1550nm

- Required testing interface QTY=log22(Output interface):log2(8)=3

High and Low Temperature Cycling Test

Loss should be within the following limits in reference to the initial value

- Variation value of Insertion Loss should be ≤0.50 dB in process of testing

- The difference between Initial Value and final test value should be ≤0.30 dB

- Return loss should be ≥50 dB in process of Testing

The test shall be conducted under the following conditions:

- High Temperature=+75℃,Temperature rate of change:1 ℃ / min

- Low Temperature=‐25℃,Temperature change rate 1 ℃ / min

- High and low temperature points to stay four hours separately

- Duration: 96h

- Cycles: 12 times

- 2 hours returned to 25℃

- Keep 2 hours at 25℃,then test

- Insertion value should be tested at least one time per 10 mins. in process of testing.

- Test Wavelength 1310‐1550nm

- Required testing interface QTY=log22(Output interface):log2(8)=3

Low Temperature Test

Loss should be within the following limits in reference to the initial value

- variation value of Insertion Loss should be ≤0.50 dB in process of testing

- The difference between Initial Value and final test value should be ≤0.30 dB

The test shall be conducted under the following conditions:

- Temperature=‐25℃

- Duration:96H

- 2 hours returned to 25℃ from ‐25℃

- Test after Keeping 2 hours at 25℃

- Insertion value should be tested at least one time per 60 mins. in process of testing.

- Test Wavelength 1310‐1550nm

- Required testing interface QTY=log22(Output interface):log2(8)=3

Dry Heat Test

Loss should be within the following limits in reference to the initial value

- Variation value of Insertion Loss should be ≤0.50 dB in process of testing

- The difference between Initial Value and final test value should be ≤0.30 dB

- Return loss should be ≥50 dB in process of Testing

The test shall be conducted under the following conditions:

- Temperature=+75℃

- Duration: 96h

- 2 hours returned to 25℃

- Test after Keeping 2 hours at 25℃

- Insertion value should be tested at least one time per 60 mins. in process of testing.

- Test Wavelength 1310‐1550nm

- Required testing interface QTY=log22(Output interface):log2(8)=3

Salt Spray Test

Loss should be within the following limits in reference to the initial value

- Variation value of Insertion Loss should be ≤0.50 dB in process of testing

- The difference between Initial Value and final test value should be ≤0.30 dB

- Return loss should be ≥50 dB in process of Testing

The test shall be conducted under the following conditions:

- Salt Spray concentration: 5%

- Condition:35℃,48H

- Test its optical performance at room temperature, and record data

- Place in salt spray chamber from the test system, heated to 35 ,then ℃ keep 48H

- Lower temperature to room temperature, remove the samples to place 2H, test the optical performance after

- No mechanical damage, such as deformation, loss, corrosion, relaxation and other phenomena

- Test Wavelength 1310‐1550nm

- Required testing interface QTY=log22(Output interface):log2(8)=3

Vibration Test

Loss should be within the following limits in reference to the initial value

- Variation value of Insertion Loss should be ≤0.50 dB in process of testing

- The difference between Initial Value and final test value should be ≤0.30 dB

- Return loss should be ≥50dB in process of testing

The test shall be conducted under the following conditions:

- Frequency:10‐55 Hz

- Amplitude:0.75mm (1.52mm Max)

- Cycles: 15 times

- Time: 90 min divided in three perpendicular directions

- Every 5 seconds to test the attenuation of at least one port

- Test Wavelength 1310‐1550nm

- Required testing interface QTY=log22(Output interface):log2(8)=3

Humidity Test

Loss should be within the following limits in reference to the initial value

- Variation value of Insertion Loss should be ≤0.50 dB in process of testing

- The difference between Initial Value and final test value should be ≤0.30 dB

- Return loss should be ≥50dB in process of testing

The test shall be conducted under the following conditions:

- Temperature=+40℃

- Humidity =93%

- Duration: 96 h

- 25℃ 2 hours returned to 25℃

- Test after Keeping 2 hours at 25℃

- Insertion value should be tested at least one time per 60 mins. in process of testing

- Test Wavelength 1310‐1550nm

- Required testing interface QTY=log22(Output interface):log2(8)=3

Water Immersion Test

Loss should be within the following limits in reference to the initial value

- Variation value of Insertion Loss should be ≤0.50 dB in process of testing

- The difference between Initial Value and final test value should be ≤0.30 dB

- Return loss should be ≥50dB in process of testing

The test shall be conducted under the following conditions:

- Elevation of water:15mm

- Temperature:43℃

- Soaking time:168 h

- Insertion value should be tested at least one time per 10 mins. in process of testing

- Test Wavelength 1310‐1550nm

- Required testing interface QTY=log22(Output interface):log2(8)=3

Flame Retardant Requirments

Test standard

- HB: UL94 standard anti‐flame retardant is the lowest grade

- Ask for 3 to 13 mm thick samples, the burning rate of less than 40 mm per minute

- Samples less than 3 mm thick, the burning rate per minute less than 70 mm or 100 mm sign is extinguished

- V‐2: After samples twice fire test for 10 seconds the flame extinguished within 60 seconds and Blazers fall

- V‐1: After samples twice fire test for 10 seconds the flame extinguished within 60 seconds and No Blazers fall

- V‐0: After samples twice fire test for 10 seconds the flame extinguished within 30 seconds. No Blazers fall

- Optical splitter, Optical cable and ABS housings should com

- Previous:1*N Tray type PLC splitter

- Next:Nothing!