-

Company Profile

Committed to the world class optical communication research and development and innovation, creating...

Patchcord Production Line

Fiber & Cable

Access Network & Datacom Solutions

Product News

Tente Fiber Fusion Splicer

Main Features

5 inches high Resolution colorful LCD display, image can be turned according to position.

Average splice time: 10 second

-

- Home

- About Us

- Product Center

- News Center

- Enterprise Culture

- Contact Us

- 中文 | ENGLISH

返回上层

- Company Profile

- Company History

- Organizational Structure

- Company Appearance

- Company Qualification

- Trademark Registration

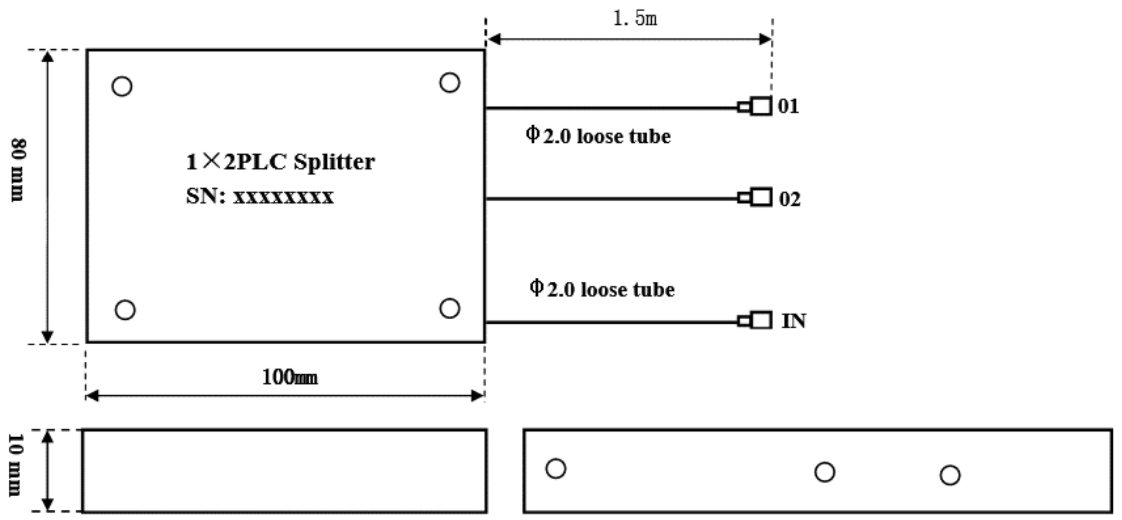

ABS cassette type PLC splitter

Specification For plc Splitter

Description

PLC(PlanarLightwaveCircuit)splittersareusedtodistributeorcombineopticalsignals.Itisbasedonplanarlightwavecircuittechnologyandprovidesalowcostlightdistributionsolutionwithsmallformfactorandhighreliability.

Fiberopticalsplitterisusedtosplitthefiberopticlightintoseveralpartsatacertainratio.ThefiberopticsplitterisanimportantpassivecomponentusedinPONFTTXnetworks.TherearemainlytwokindsofpassiveFTTHopticalsplitters:oneisthetraditionalfusedtypesplitterasknownasFBTcouplerorFBTWDMopticalsplitter,whichfeaturescompetitiveprice;theotheristhePLCsplitterbasedonthePLC(PlanarLightwaveCircuit)technology,which has a compact size and suits for density applications.

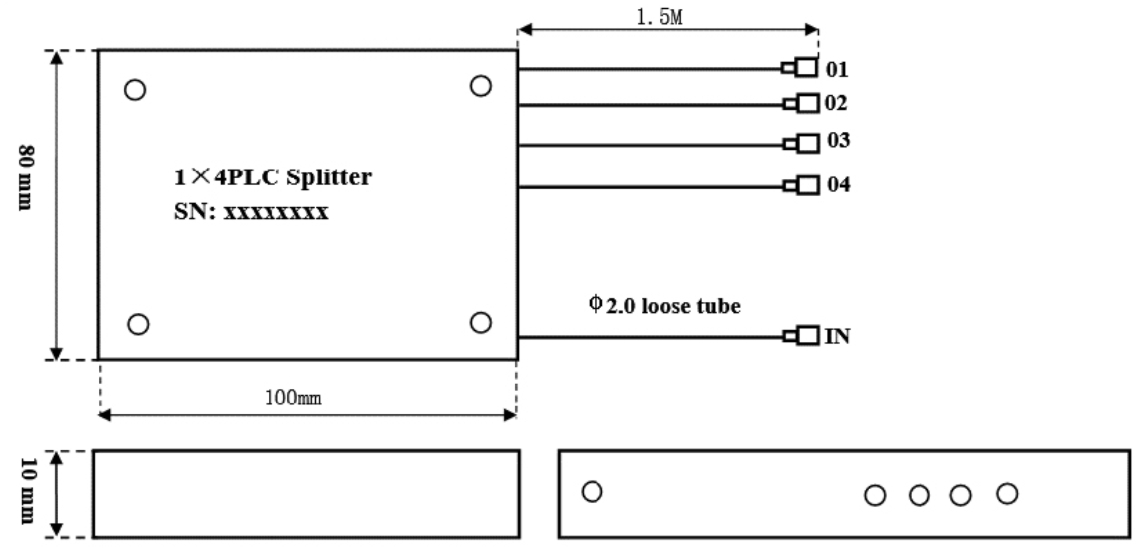

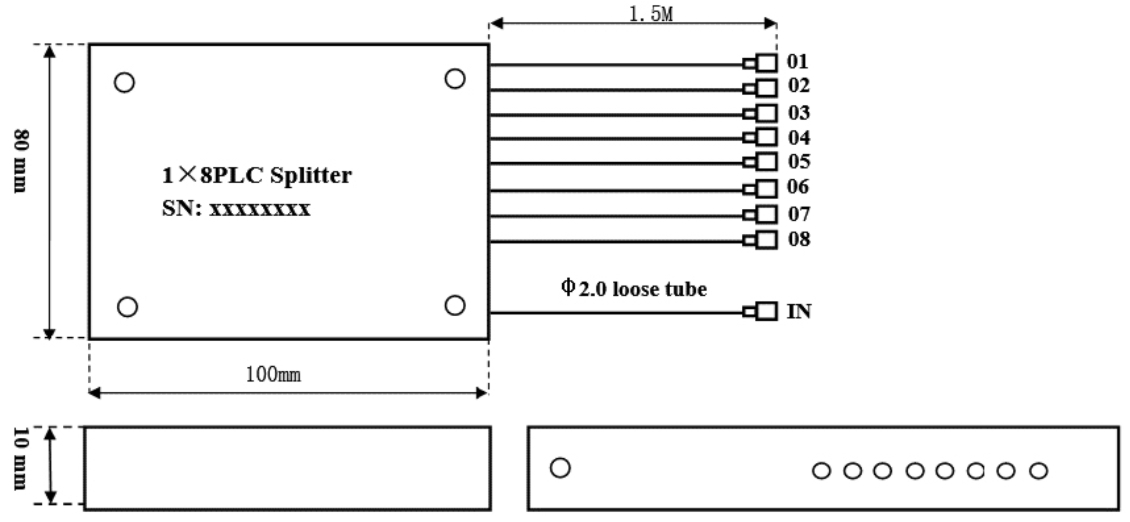

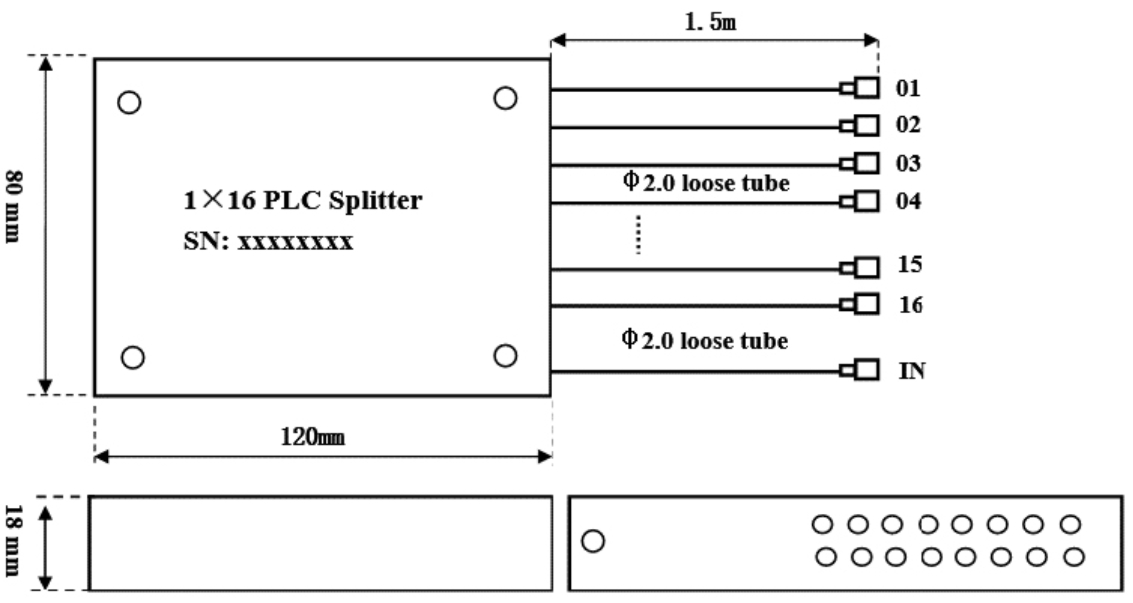

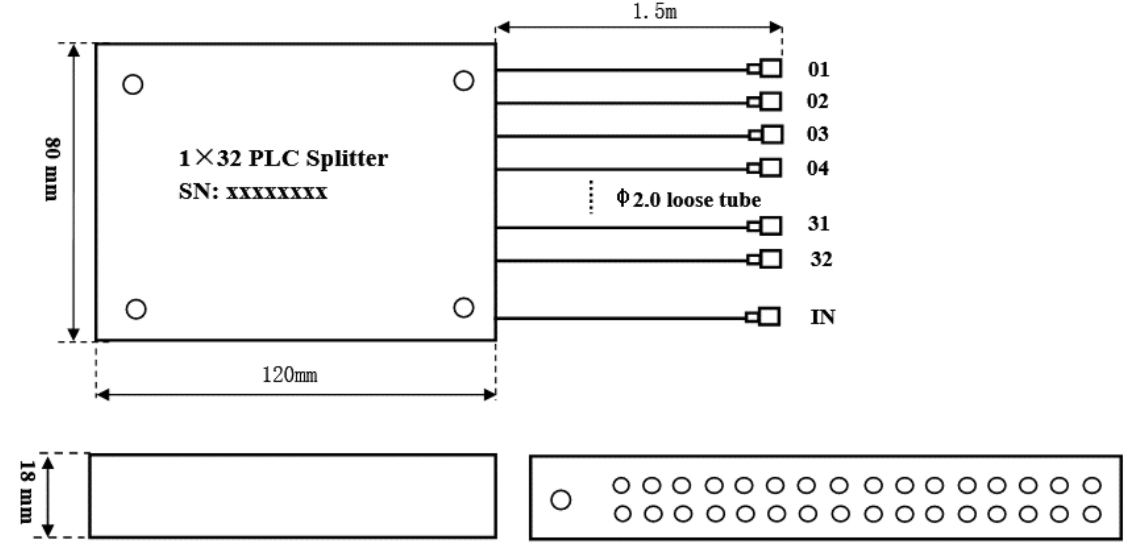

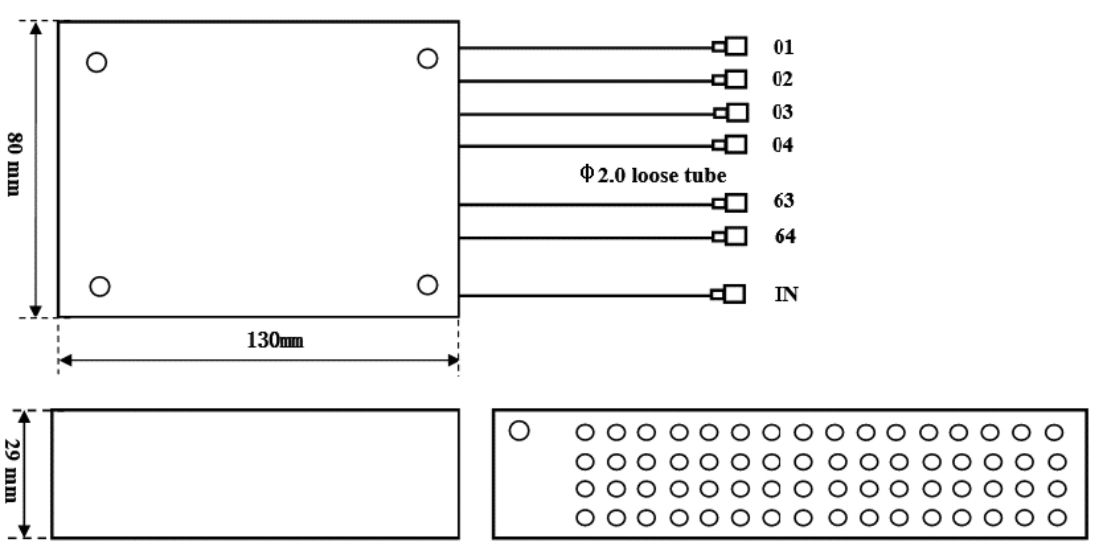

3. ABS cassette type PLC splitter

Input port | 1 or 2 | |||||

Output port | 2 | 4 | 8 | 16 | 32 | 64 |

Dimension (nm) | 100*80*10 | 120*80*18 | 130*80*29 | |||

Housing material | PC+ABS Plastic (black) | |||||

Port configuration | 2.0mm pigtails | |||||

Connector type | SC/FC/ST/LC with PC/PC/APC | |||||

|

| |

| 1*2 Cassette type PLC splitter | ||

|  | |

| 1*4 Cassette type PLC splitter | ||

|  | |

| 1*8 Cassette type PLC splitter |

|  | |

| 1*16 Cassette type PLC splitter | ||

|  | |

| 1*32 Cassette type PLC splitter | ||

|  | |

| 1*64 Cassette type PLC splitter |

PLC Test Specification

Insert/Pull Test

Loss should be within the following limits in reference to the initial value:

- Variation value of Insertion Loss should be ≤0.50 dB in process of testing

- The difference between Initial Value and final test value should be ≤0.30 d

- Return loss should be ≥50 dB in process of Testing

The test shall be conducted under the following conditions:

- Pull/Insert:500 times

- Record a data every 10 times

- Data is recorded 50 times in total

- Clean pins and adapter’s elastic sleeve before recording very time

- Not mechanical damage, such as deformation, loss, corrosion, relaxation and other phenomena

- Test Wavelength 1310‐1550nm

- Required testing interface QTY=log22(Output interface):log2(8)=3

Tensile Test

Loss should be within the following limits in reference to the initial value

- Variation value of Insertion Loss should be ≤0.50 dB in process of testing

- The difference between Initial Value and final test value should be ≤0.30 dB

- Return loss should be ≥55 dB in process of Testing

The test shall be conducted under the following conditions:

- Load: 4 N

- Tensile variation in process of testing: 1N/s

- Duration:60s

- Tensile Point:0.22‐0.28m distance from fiber cable ends

- Test Wavelength 1310‐1550nm

- Required testing interface QTY=log22(Output interface):log2(8)=3

Torsion Test

Loss should be within the following limits in reference to the initial value

- Variation value of Insertion Loss should be ≤0.50 dB in process of testing

- The difference between Initial Value and final test value should be ≤0.30 dB

- Return loss should be ≥50 dB in process of Testing

The test shall be conducted under the following conditions:

- Applied force:7.4N

- The distance between the Torsion point and shell underside is 0.2cm

- Max Torsion Angle: ±180°

- Number of torsions: 100 times

- Torsion Speed:10 Times/min.

- Test Wavelength 1310‐1550nm

- Required testing interface QTY=log22(Output interface):log2(8)=3

High and Low Temperature Cycling Test

Loss should be within the following limits in reference to the initial value

- Variation value of Insertion Loss should be ≤0.50 dB in process of testing

- The difference between Initial Value and final test value should be ≤0.30 dB

- Return loss should be ≥50 dB in process of Testing

The test shall be conducted under the following conditions:

- High Temperature=+75℃,Temperature rate of change:1 ℃ / min

- Low Temperature=‐25℃,Temperature change rate 1 ℃ / min

- High and low temperature points to stay four hours separately

- Duration: 96h

- Cycles: 12 times

- 2 hours returned to 25℃

- Keep 2 hours at 25℃,then test

- Insertion value should be tested at least one time per 10 mins. in process of testing.

- Test Wavelength 1310‐1550nm

- Required testing interface QTY=log22(Output interface):log2(8)=3

Low Temperature Test

Loss should be within the following limits in reference to the initial value

- variation value of Insertion Loss should be ≤0.50 dB in process of testing

- The difference between Initial Value and final test value should be ≤0.30 dB

The test shall be conducted under the following conditions:

- Temperature=‐25℃

- Duration:96H

- 2 hours returned to 25℃ from ‐25℃

- Test after Keeping 2 hours at 25℃

- Insertion value should be tested at least one time per 60 mins. in process of testing.

- Test Wavelength 1310‐1550nm

- Required testing interface QTY=log22(Output interface):log2(8)=3

Dry Heat Test

Loss should be within the following limits in reference to the initial value

- Variation value of Insertion Loss should be ≤0.50 dB in process of testing

- The difference between Initial Value and final test value should be ≤0.30 dB

- Return loss should be ≥50 dB in process of Testing

The test shall be conducted under the following conditions:

- Temperature=+75℃

- Duration: 96h

- 2 hours returned to 25℃

- Test after Keeping 2 hours at 25℃

- Insertion value should be tested at least one time per 60 mins. in process of testing.

- Test Wavelength 1310‐1550nm

- Required testing interface QTY=log22(Output interface):log2(8)=3

Salt Spray Test

Loss should be within the following limits in reference to the initial value

- Variation value of Insertion Loss should be ≤0.50 dB in process of testing

- The difference between Initial Value and final test value should be ≤0.30 dB

- Return loss should be ≥50 dB in process of Testing

The test shall be conducted under the following conditions:

- Salt Spray concentration: 5%

- Condition:35℃,48H

- Test its optical performance at room temperature, and record data

- Place in salt spray chamber from the test system, heated to 35 ,then ℃ keep 48H

- Lower temperature to room temperature, remove the samples to place 2H, test the optical performance after

- No mechanical damage, such as deformation, loss, corrosion, relaxation and other phenomena

- Test Wavelength 1310‐1550nm

- Required testing interface QTY=log22(Output interface):log2(8)=3

Vibration Test

Loss should be within the following limits in reference to the initial value

- Variation value of Insertion Loss should be ≤0.50 dB in process of testing

- The difference between Initial Value and final test value should be ≤0.30 dB

- Return loss should be ≥50dB in process of testing

The test shall be conducted under the following conditions:

- Frequency:10‐55 Hz

- Amplitude:0.75mm (1.52mm Max)

- Cycles: 15 times

- Time: 90 min divided in three perpendicular directions

- Every 5 seconds to test the attenuation of at least one port

- Test Wavelength 1310‐1550nm

- Required testing interface QTY=log22(Output interface):log2(8)=3

Humidity Test

Loss should be within the following limits in reference to the initial value

- Variation value of Insertion Loss should be ≤0.50 dB in process of testing

- The difference between Initial Value and final test value should be ≤0.30 dB

- Return loss should be ≥50dB in process of testing

The test shall be conducted under the following conditions:

- Temperature=+40℃

- Humidity =93%

- Duration: 96 h

- 25℃ 2 hours returned to 25℃

- Test after Keeping 2 hours at 25℃

- Insertion value should be tested at least one time per 60 mins. in process of testing

- Test Wavelength 1310‐1550nm

- Required testing interface QTY=log22(Output interface):log2(8)=3

Water Immersion Test

Loss should be within the following limits in reference to the initial value

- Variation value of Insertion Loss should be ≤0.50 dB in process of testing

- The difference between Initial Value and final test value should be ≤0.30 dB

- Return loss should be ≥50dB in process of testing

The test shall be conducted under the following conditions:

- Elevation of water:15mm

- Temperature:43℃

- Soaking time:168 h

- Insertion value should be tested at least one time per 10 mins. in process of testing

- Test Wavelength 1310‐1550nm

- Required testing interface QTY=log22(Output interface):log2(8)=3

Flame Retardant Requirments

Test standard

- HB: UL94 standard anti‐flame retardant is the lowest grade

- Ask for 3 to 13 mm thick samples, the burning rate of less than 40 mm per minute

- Samples less than 3 mm thick, the burning rate per minute less than 70 mm or 100 mm sign is extinguished

- V‐2: After samples twice fire test for 10 seconds the flame extinguished within 60 seconds and Blazers fall

- V‐1: After samples twice fire test for 10 seconds the flame extinguished within 60 seconds and No Blazers fall

- V‐0: After samples twice fire test for 10 seconds the flame extinguished within 30 seconds. No Blazers fall

- Optical splitter, Optical cable and ABS housings should com

- Previous:Insertion type PLC splitter

- Next:1*N Tray type PLC splitter