-

Company Profile

Committed to the world class optical communication research and development and innovation, creating...

Patchcord Production Line

Fiber & Cable

Access Network & Datacom Solutions

Product News

Tente Fiber Fusion Splicer

Main Features

5 inches high Resolution colorful LCD display, image can be turned according to position.

Average splice time: 10 second

-

- Home

- About Us

- Product Center

- News Center

- Enterprise Culture

- Contact Us

- 中文 | ENGLISH

返回上层

- Company Profile

- Company History

- Organizational Structure

- Company Appearance

- Company Qualification

- Trademark Registration

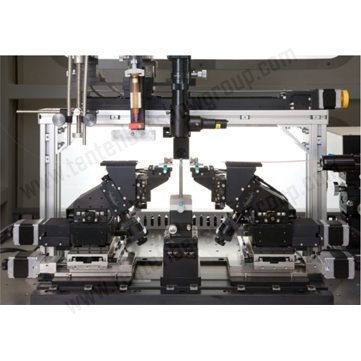

PLC auto-encapsulation system

PLC auto-encapsulation system

Three Programs of P LC Optical Splitter System

1 Six-dimensional adjustment frame is made with Japan Suruga Seiki, and other parts are all domestic, which do not affect the efficiency. Meanwhile Suruga Seiki's six-dimensional adjustment is not oblique 8 degrees and we have our own processing center, so we can transform it to improve the efficiency.

2.For large-scale production enterprise, I recommend the use of fully automatic packaging system, which fully imported from Japan, with the advantages of high efficiency, product consistency, more mature technology and perfect training.

3.all the parts we can all achieve localization.Our technical staff in the industry have 10 years of work experience. For preliminary research institutes involved in this area, domestic products are recommended to do predicted experiments, so that it can save cost and produce results.

(Fused Fiber Splitter)

FBT(Fused Biconic Tapered) Optical Splitter

Fused taper technique is to bundle two or more fibers together and melt in the pull-cone machine and stretch, monitoring splitting ratio changes. Melt pull extension should be concluded after splitting ratio meets the requirements. One end of an optical fiber retention (rest cut off) as an input, and the other end is multi- road output. Currently mature tapering process can only pull 1 × 4 below. 1 × 4 or more devices, then Connected together by a plurality of 1 × 2. Then the whole package in the splitter box.

Main advantages:

(1) FBT coupler technology enjoys over twenty years of history and experience, a lot of equipment and process just follow it, only costs a tenths or even a few hundredths of PLC.

(2) only readily available raw materials, such as quartz substrate,fiber optics, heat shrink tubing, stainless steel tube and less plastic are needed. Total cost is not more than one US dollar, while it can invest more less in machinery and equipment. With less 1 × 2,1 × 4 channel splitter, low cost do.

(3) splitting ratio can be real-time monitoring as needed, you can create unequal splitter.

Main disadvantages:

(1) Loss of optical fiber is sensitive to wavelength, generally depending on the wavelength to select device, which is a fatal flaw in the use of triple-play process, because the transmission of optical signals have 1 3 1 0 nm, 1 4 9 0 nm, 1 5 5 0 nm wavelength signals, ect.

(2) Poor uniformity, 1 X 4 nominal maximum difference is about 1. 5 d B, 1 × 8 or more greater difference. Spectral uniformity can not be ensured, which may affect the overall transmission distance.

(3) Large insertion loss variation with temperature change (TDL)

(4)Demultiplexers(e.g. 1 × 1 6,1 × 3 2) have relatively large size. The reliability will be reduced,and the installation space is limited.

(5) Compact structure, small size, can be installed directly in the various existing junction box.

PLC Splitter

Planar optical waveguide technology produces optical waveguide branching components with semiconductor fabrication technique to. Shunt function on the chip is completed, you can achieve up to 1 X 3 2 or more branches on one chip, then package input and output end multi-channel fiber array are coupled at two ends of the chip.

Main advantages:

1) Loss of optical fiber is insensitive to wavelength, meeting the needs of different transmission wavelengths.

(2) the spectral uniformity, signal can be evenly distributed to the user.

(3) compact structure, small size. It can be installed directly in the various existing junction box, without special design to leave a lot of installation space.

(4) single-channel devices shunt lot, you can reach more than 32 roads.

(5) multi-channel cost less, the more points, the more obvious cost advantages.

Main disadvantages:

(1) Complicate device fabrication process , high technical threshold, currently monopolized by foreign several chip companies. There a few domestic companies who can produce bulk packaging.

(2)more expensive than FBT technology, especially more disadvantaged in the low channel splitter.

- Previous:Manual focusing machine

- Next:PLC workbench