-

Company Profile

Committed to the world class optical communication research and development and innovation, creating...

Patchcord Production Line

Fiber & Cable

Access Network & Datacom Solutions

Product News

Tente Fiber Fusion Splicer

Main Features

5 inches high Resolution colorful LCD display, image can be turned according to position.

Average splice time: 10 second

-

- Home

- About Us

- Product Center

- News Center

- Enterprise Culture

- Contact Us

- 中文 | ENGLISH

返回上层

- Company Profile

- Company History

- Organizational Structure

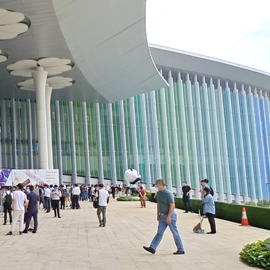

- Company Appearance

- Company Qualification

- Trademark Registration

--361-副本_8857.jpg)

Stranded Loose Tube Light-armored Cable (GYTA53+33)

Stranded Loose Tube Light-armored Cable (GYTA53+33)

Description

The fibers, 250µm, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. A steel wire, sometimes sheathed with polyethylene (PE) for cable with high fiber count, locates in the center of core as a metallic strength member. Tubes (and fillers) are stranded around the strength member into a compact and circular cable core. The PSP is longitudinally applied over the cable core, which is filled with the filling compound to protect it from water ingress. The cable is completed with a PE sheath.

Characteristics

Good mechanical and temperature performance

High strength loose tube that is hydrolysis resistant

Special tube filling compound ensure a critical protection of fiber

Specially designed compact structure is good at preventing loose tubes from shrinking

Crush resistance and flexibility

PE sheath protects cable from ultraviolet radiation

The following measures are taken to ensure the cable watertight:

Steel wire used as the central strength member

Loose tube filling compound

100% cable core filling

PSP enhancing moisture-proof

Standards

GYTA53 cable complies with Standard YD/T 901-2001 as well as IEC 60794-1.

Application: Duct/ Aerial/Direct buried

Optical Characteristics

G.652 | G.655 | 50/125 µm | 62.5/125 µm | ||

Attenuation(+20℃) | @ 850 nm | ≤ 3.0 dB/km | ≤ 3.0 dB/km | ||

@1300 nm | ≤ 1.0 dB/km | ≤ 1.0 dB/km | |||

@1310 nm | ≤ 0.36 dB/km | ≤ 0.40 dB/km | |||

@1550 nm | ≤ 0.22 dB/km | ≤ 0.23 dB/km | |||

Bandwidth(Class A) | @ 850 nm | ≥ 500 MHz·km | ≥ 200 MHz·km | ||

@1300 nm | ≥ 1000 MHz·km | ≥ 600 MHz·km | |||

Numerical Aperture | 0.200 ± 0.015 NA | 0.275 ± 0.015 NA | |||

Cable Cut-off Wavelength lcc | ≤ 1260 nm | ≤ 1450 nm | |||

Technical Parameters

Cable Type | Fiber Count | Tubes | Fillers | Cable Diameter | Cable Weight | Tensile Strength | Crush Resistance | Bending Radius |

GYTA53+33-2~6Xn | 2~6 | 1 | 5 | 22.1 | 819 | 4000/10000 | 3000/5000 | 12.5D/25D |

GYTA53+33-8~12Xn | 8~12 | 2 | 4 | 22.1 | 819 | 4000/10000 | 3000/5000 | 12.5D/25D |

GYTA53+33-14~18Xn | 14~18 | 3 | 3 | 22.1 | 819 | 4000/10000 | 3000/5000 | 12.5D/25D |

GYTA53+33-20~24Xn | 20~24 | 4 | 2 | 22.1 | 819 | 4000/10000 | 3000/5000 | 12.5D/25D |

GYTA53+33-26~30Xn | 26~30 | 5 | 1 | 22.1 | 819 | 4000/10000 | 3000/5000 | 12.5D/25D |

GYTA53+33-32~36Xn | 32~36 | 6 | 0 | 22.1 | 819 | 4000/10000 | 3000/5000 | 12.5D/25D |

GYTA53+33-2~6Xn | 2~6 | 1 | 5 | 23.1 | 1002 | 10000/20000 | 3000/5000 | 12.5D/25D |

GYTA53+33-8~12Xn | 8~12 | 2 | 4 | 23.1 | 1002 | 10000/20000 | 3000/5000 | 12.5D/25D |

GYTA53+33-14~18Xn | 14~18 | 3 | 3 | 23.1 | 1002 | 10000/20000 | 3000/5000 | 12.5D/25D |

GYTA53+33-20~24Xn | 20~24 | 4 | 2 | 23.1 | 1002 | 10000/20000 | 3000/5000 | 12.5D/25D |

GYTA53+33-26~30Xn | 26~30 | 5 | 1 | 23.1 | 1002 | 10000/20000 | 3000/5000 | 12.5D/25D |

GYTA53+33-32~36Xn | 32~36 | 6 | 0 | 23.1 | 1002 | 10000/20000 | 3000/5000 | 12.5D/25D |

Note:Storage/Operating Temperature: -40℃ to +70℃

Note:

a. Suffix Xn denotes fiber type .

b. The colour arrangements of fiber and tube are specified in the colour identification table.

c. The nominal value of the outer sheath thickness is 2.2mm; the nominal value of the PE outer sheath thickness is 2.0mm; and the nominal value of the PE inner sheath thickness is 1.0mm.